From Metal Scraps to Superior Steel: The American Wire Story

From Metal Scraps to Superior Steel: The American Wire Story

In a world increasingly dominated by disposable products, the recycling and repurposing of materials stand out as a beacon of sustainability and resourcefulness. At the heart of this is the story of American-made steel wire, particularly the kind Midwest Bale Ties is proud to work with.

Collection of Scrap Metal

The journey starts in scrapyards, factories, and homes across the U.S. Old cars, discarded appliances, and construction debris, among others, serve as goldmines for the valuable scrap metal that forms the base of our steel wire.

melting and refinement

This collected scrap metal is then transported to steel mills. Here, it’s melted down in large furnaces. The impurities, often called “slag”, rise to the top and are removed. What remains is molten steel, ready for shaping and refining.

Drawing and Shaping

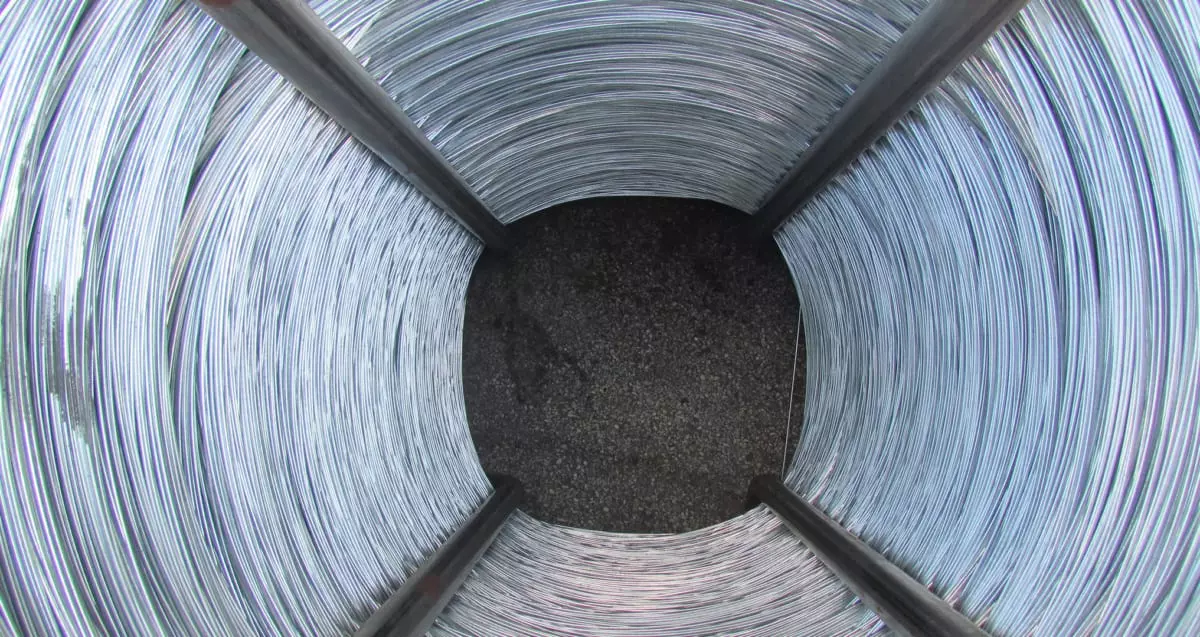

Once the molten steel is at the desired purity and consistency, it’s drawn into wire forms. It’s passed through a series of dies that progressively decrease in size, allowing for the creation of steel wire of various diameters suitable for different applications.

Crafting Midwest Bale Ties and Wire Products

The wire, once formed, is now ready for transformation into the diverse range of products Midwest Wire offers:

- Baler & Box Wire: Essential for bundling and ensuring materials remain intact.

- Ceiling and Hanging Wire: Crafted for durability and strength, perfect for support systems.

- Straight and Cut Wire: Precisely cut to fit an array of applications.

- Stump and Stem Wire: Specialized wires for unique industrial tasks.

Quality Assurance

Every piece of wire and every product undergoes stringent checks. It’s not just about meeting industrial benchmarks, but upholding the promise of American quality and the unmatched durability of steel.

Discover the Difference of American Craftsmanship! Dive deeper into our range of products and see firsthand the quality and precision of Midwest Bale Ties.

The Role of Midwest Bale Ties’ Galvanized Wire in Powder Coating

The Role of Midwest Bale Ties’ Galvanized Wire in Powder Coating

Galvanized wire is celebrated for its durability, rust resistance, and versatility, offering a host of applications in various industries. At Midwest Bale Ties, we’re proud to provide top-tier galvanized wire that can stand the test of time, proving essential even in niche applications like powder coating. This blog post dives into how our galvanized wire significantly contributes to the powder coating process.

What is Galvanized Wire?

Our galvanized wire is made by dipping steel wire into molten zinc, a process known as hot-dip galvanization. This results in a protective layer of zinc that resists rust and corrosion, making the wire suitable for long-term use in challenging environments.

Midwest Bale Ties’ galvanized wire is renowned for its consistent quality, high strength, and reliable performance, making it an excellent choice for industries that require long-lasting, corrosion-resistant wire.

Application in Powder Coating

Powder coating is a finishing process used primarily for metal objects. It involves applying a dry, free-flowing powder (usually a thermoplastic or a thermoset polymer) to a surface, which is then heated (cured) to form a protective, decorative finish that is tougher and longer-lasting than conventional paint.

Midwest Bale Ties’ galvanized wire plays a critical role in this process. The items to be coated are often hung on wire racks before undergoing the powder coating process. Here, the quality and strength of the wire used are paramount, as it must withstand not only the weight of the items but also the high curing temperatures, which can reach up to 200°C (392°F).

Our galvanized wire, with its robust strength and superior heat resistance, is the perfect candidate for the job. Its high melting point ensures it remains stable and maintains its integrity throughout the heat-intensive curing process. In addition, its corrosion-resistant properties make it suitable for repeated use, even in harsh powder coating environments.

Moreover, the galvanized wire’s clean, smooth surface ensures it does not interfere with the powder coating process by introducing contaminants, ensuring a high-quality, consistent finish.

Take the Next Step

Midwest Bale Ties’ galvanized wire’s strength, durability, and resistance to heat and corrosion make it an invaluable asset in the powder coating industry. The wire’s superior qualities not only aid in the efficient application of powder coating but also contribute to a superior final finish, making it a go-to choice for businesses in this sector.

If you’re in the powder coating business and need high-quality galvanized wire that delivers excellent results, look no further than Midwest Bale Ties. For inquiries or more information, call our sales team today at 765-364-0113.

How to Properly Size a Bale Tie: What Size Bale Tie Do I Need?

How to Properly Size a Bale Tie: What Size Bale Tie Do I Need?

Measure your bale

Weigh your bale

Understand what is being baled

Count your wires

Looking For Bale Ties in the Midwest?

Galvanized vs. Black Annealed: What’s the Difference?

Galvanized vs. Black Annealed: What’s the Difference?

Galvanized Wire

How do you Make Galvanized Wire?

Black Annealed Wire

What is Black Annealing?

Painted or Coated Wire

What is Coated Wire?

What is Baling Wire Made Of?

4 Important Questions to Ask When Purchasing Bale Ties and Baler Wire

4 Important Questions to Ask When Purchasing Bale Ties and Baler Wire

What are we baling?

Where are our bales being stored and for how long?

How much do your bales weigh?

What are the dimensions of your bales?

How to Save Money on Bale Ties: Sizing, Quantity, and Freight

How to Save Money on Bale Ties: Sizing, Quantity, and Freight

Sizing

Quantity

Freight

Why are Bale Ties and Baling Wire Essential?

Why are Bale Ties and Baling Wire Essential?

Value: What Does Your Baler Wire, Bale Ties, and Hi-Tensile Wire Supplier Do to Help Your Business?

Value: What Does Your Baler Wire, Bale Ties, and Hi-Tensile Wire Supplier Do to Help Your Business?

Monitor and Ensure Quality

Education

Dependability and Timeliness

Packaging and Flexibility

What’s in Your Baler?

What’s in Your Baler?

Paper

Plastic

Non-ferrous metals

Textiles

Foam

Tires

E-Waste

Hay

Why American-Made Bale Ties Are Your Best Bet for Quality and Safety

Why American-Made Bale Ties Are Your Best Bet for Quality and Safety